My friend Mamudu and his family originally came from the Mossi region of Burkina Faso. But after spending over several generations in Navrongo his family speaks both Kasem and Nankani. Their house is a well known rest stop for Burkinabé seeking a rest-house while they or their family members receive treatment at Navrongo's War Memorial Hospital. Mamudu and his family are farmers like everyone else but they also make bronze bangles using the "lost-wax" method. This page will describe that method.

Stock materials used in the process include: Candle and bees wax, clay from the earth and termite mounds, old spent radiator grills and other scrap metal, wooden shaping boards and rollers, and a gerry-rigged billow using an old bicycle wheel connected by a rubber pulley to a rotary air blower.

|

The first step is to soften the candle and bees wax by rolling and smoothing it on wooden boards. Once soft enough, it is molded into the shape of a bangle. There are many different styles. Up to seven or eight wax bangles are made in a group. |

| The second step involves carefully packing an earthen and termite clay mix around the wax bangles. Each wax bangle is entirely surrounded by the clay mix.

The clay packed wax bangles are then grouped together with a open end at the top. You can see a set of clay packed wax bangles on the wooden board at the left. Individual holes are made from this open top to each clay pack clay bangle. |

|

The bundle of clay packed wax bangles are then fired in a charcoal pit. The pit is heated to over 1000 degrees Celsius by using a bicycle wheel driven air blower. The operator of the pit spins the wheel with a stick and this rotates the air blower. The air is forced into the bottom of the charcoal pit through a clay funnel. As the clay packed mold is fired the wax inside is melted. The melted wax is poured out and saved for re-use. An empty space is created which matches the shapes of the wax bangles. |

|

The next step involves melting scrap metal in a clay crucible. Most of the scrap metal is bronze and comes from spent car and truck radiators. The crucible is stirred to ensure that all of the metal is melted. When the metal is glowing white hot and completely melted it is then poured into the clay packed mold. The space that was once filled with the wax bangle is now filled with liquid metal. The liquid metal fills the empty space and takes the space of the wax bangle. |

|

The bangles are allowed to cool for a little while to let the metal solidify. When sufficiently cooled the clay is broken off of the metal bangles. The metal bangles are still very hot and they are placed in water to cool them off. The bangles are then polished. |

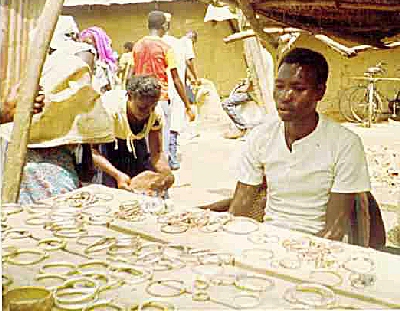

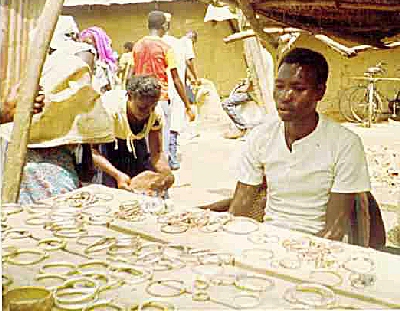

| Here's Mamudu in the Navrongo market with the finished product. They generally retail for approximately twenty-fifty cents. |

Back to the Main Page

Back to the Main Page

Back to the Culture Page

Back to the Culture Page

Back to the Main Page

Back to the Main Page Back to the Culture Page

Back to the Culture Page